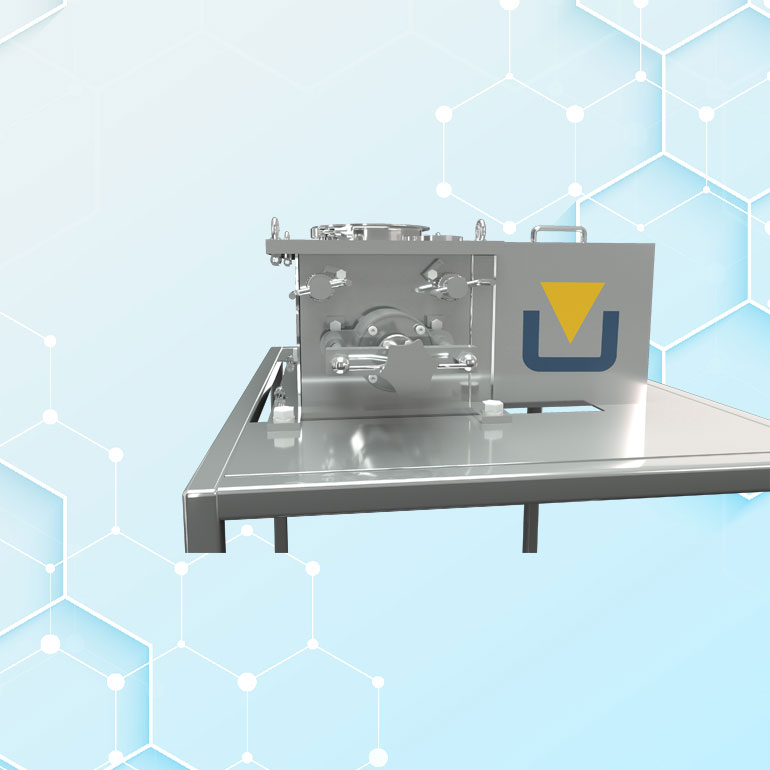

Oscillating Granulator Manufacturer / Supplier / Exporter

High Speed Uniform Granulation Process

Application & Process :

The Oscillating Granulator, manufactured by AURUS, is a highly efficient and reliable pharmaceutical machine designed for granulation and size reduction processes. It is known for its exceptional performance and precision in producing uniform and high-quality granules.

Function and Operation : The Oscillating Granulator operates through a unique oscillating motion that facilitates the granulation process. The material is fed into the granulating chamber, where a rotating impeller creates a controlled oscillating movement. This movement forces the material through a sieve screen, resulting in the formation of uniform and consistent granules. The adjustable speed and amplitude settings allow for precise control over the granule size.

Usage and Applications : The Oscillating Granulator finds widespread usage in the pharmaceutical industry for the production of granules from a variety of materials, including dry and wet powders. It is particularly suitable for materials that require controlled and gentle granulation, such as pharmaceutical ingredients, herbs, and excipients. The granules produced by the Oscillating Granulator are commonly used in tablet manufacturing, enabling improved flowability, compressibility, and uniform drug distribution.

Capacity and Models : AURUS offers a range of Oscillating Granulator models with different capacities to cater to various production requirements. The Oscillating Granulator is available in different sizes, allowing you to choose the model that suits your specific needs. Whether you need a smaller capacity for laboratory-scale research and development or a larger capacity for high-volume production, AURUS has the right Oscillating Granulator to meet your demands.

The Oscillating Granulator, manufactured by AURUS, not only delivers exceptional granulation performance but also prioritizes operator safety. With a strong focus on ensuring a secure working environment, the machine incorporates several safety features.

Operator Safety Features : The Oscillating Granulator is designed with safety in mind. It is equipped with protective guards and interlocks to prevent unauthorized access to the granulating chamber during operation, minimizing the risk of accidents. Additionally, the machine is engineered to reduce noise levels, creating a safer and more comfortable working environment for operators.

Compliance with International Standards : AURUS understands the importance of meeting international safety standards and regulations. The Oscillating Granulator can be provided with certifications as per ATEX (Atmospheres Explosibles) and UL (Underwriters Laboratories) standards, ensuring compliance with international safety requirements. These certifications validate the machine's ability to operate safely in potentially hazardous environments and demonstrate its adherence to stringent safety guidelines.

ATEX certification ensures that the Oscillating Granulator is designed and constructed to prevent the ignition of explosive atmospheres that may be present in certain manufacturing settings. It guarantees the machine's suitability for use in potentially explosive environments, providing peace of mind in terms of operator safety.

UL certification signifies that the Oscillating Granulator has undergone rigorous testing and evaluation to meet the safety standards established by Underwriters Laboratories. This certification ensures that the machine meets industry-recognized safety criteria and can be trusted for safe and reliable operation.

By incorporating these safety features and offering certifications as per ATEX and UL standards, AURUS demonstrates its commitment to providing pharmaceutical machinery that not only delivers superior performance but also prioritizes the well-being of operators. Contact us today to learn more about our Oscillating Granulator, its safety features, and how it can enhance your granulation processes. Our team of experts is ready to provide detailed information, discuss international requirements, and assist you in selecting the ideal Oscillating Granulator that meets both your safety and production needs. Take the next step towards a safer and more efficient granulation process by reaching out to us now.

Salient Features :

- Design is cGMP - Current Good Manufacturing Practices compliance

- All Product contact parts AISI 316 & non contact parts AISI 304.

- Uniformly granulation & fewer fines of wet material and dry materials.

- Rotor move oscillating motion with 180 stroke per minute.

- Easy to operate; move, clean, convenient.

- An Inline granulation & user friendly.

- Zero dusting & maintenance free.

Optional Features :

- Flame proof motor and Push Button Station.

- Inline granulation with Roll compactor & Tipper with FBD Bowl.

Safety Features :

- Limit switch at charging hopper & over load relay protection.

| MODEL | SG-250 | SG-500 |

|---|---|---|

| Output | 100 - 400 Kg / Hour | 200 - 800 Kg / Hour |

| Oscillating Speed | 180 per minute | 180 per minute |

| Motor | 2 hp | 2 hp X 2 Nos. |

| Power | 1.5 Kw/3 ph/415 V/50 Hz | 3 Kw/3 ph/415 V/50 Hz |